Quick release hook

Retail Price

Market price

Weight

Inventory

隐藏域元素占位

- Product Description

-

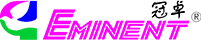

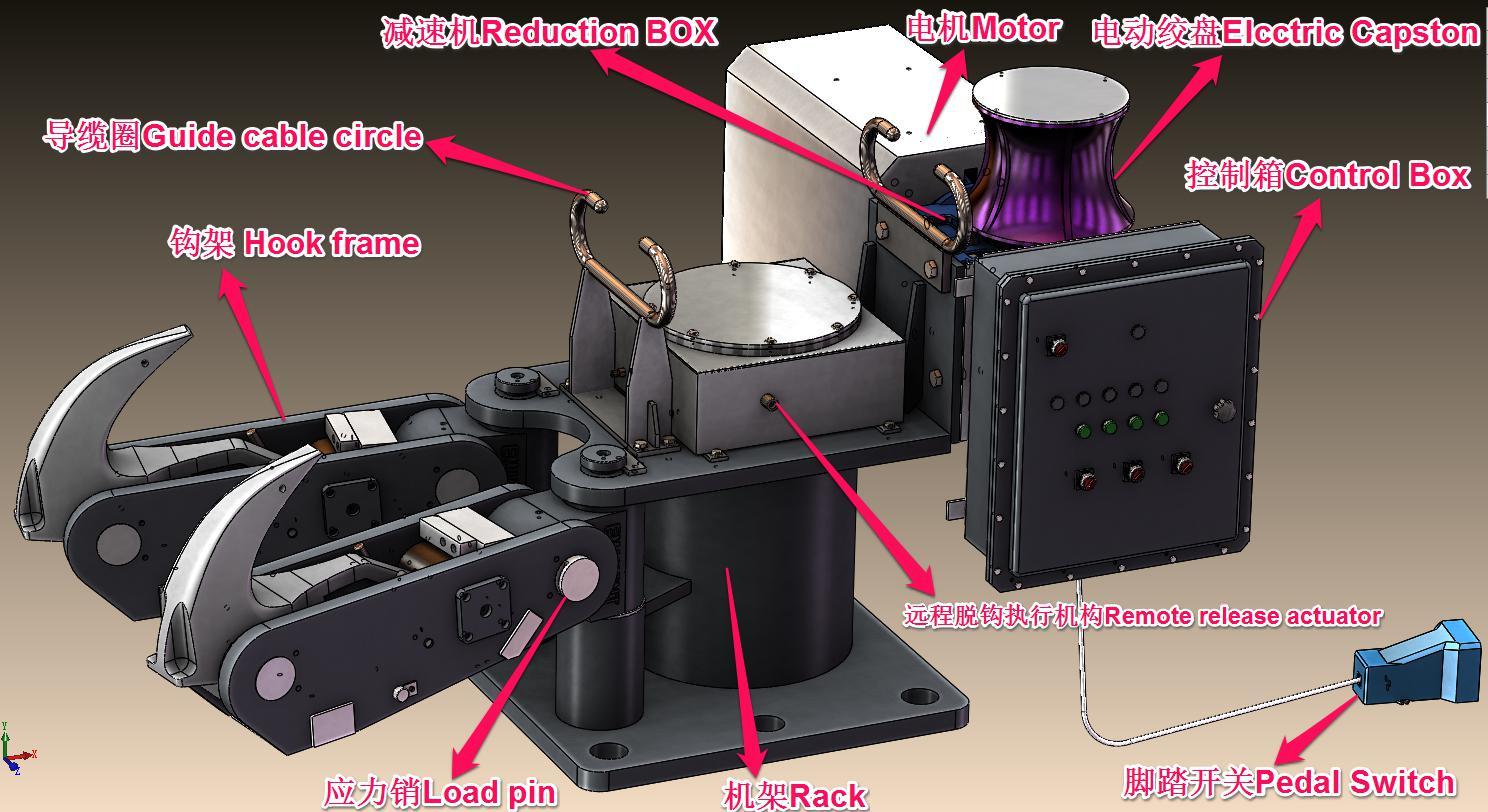

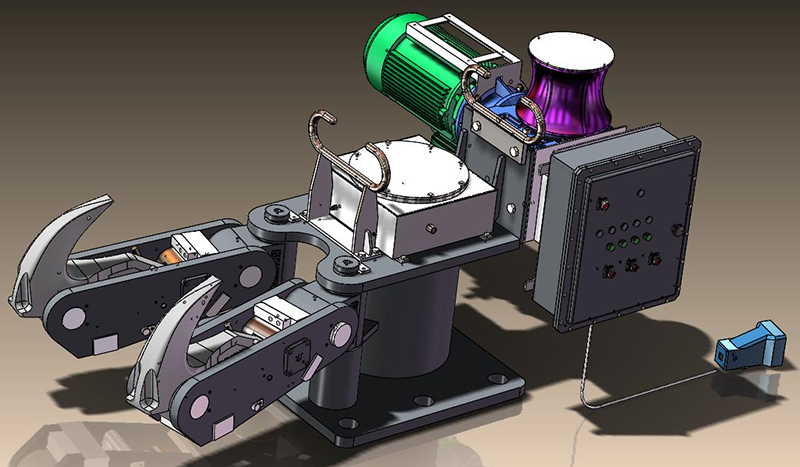

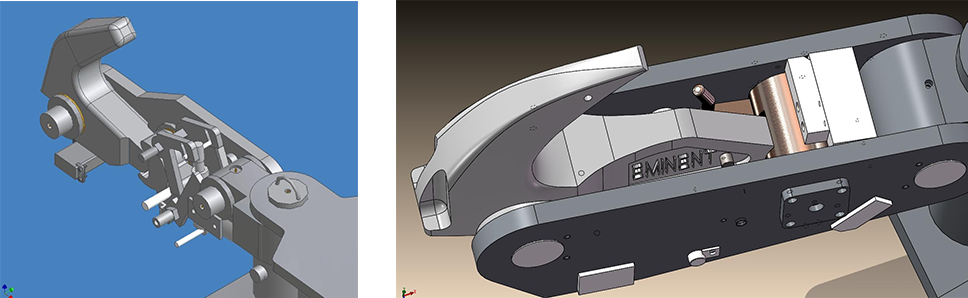

Quick release hook components

Quick release hook structure

The quick release hook includes a hook body and a basic frame made of alloy steel. It is an easy-to-disassemble structure assembled with shafts and bolts.

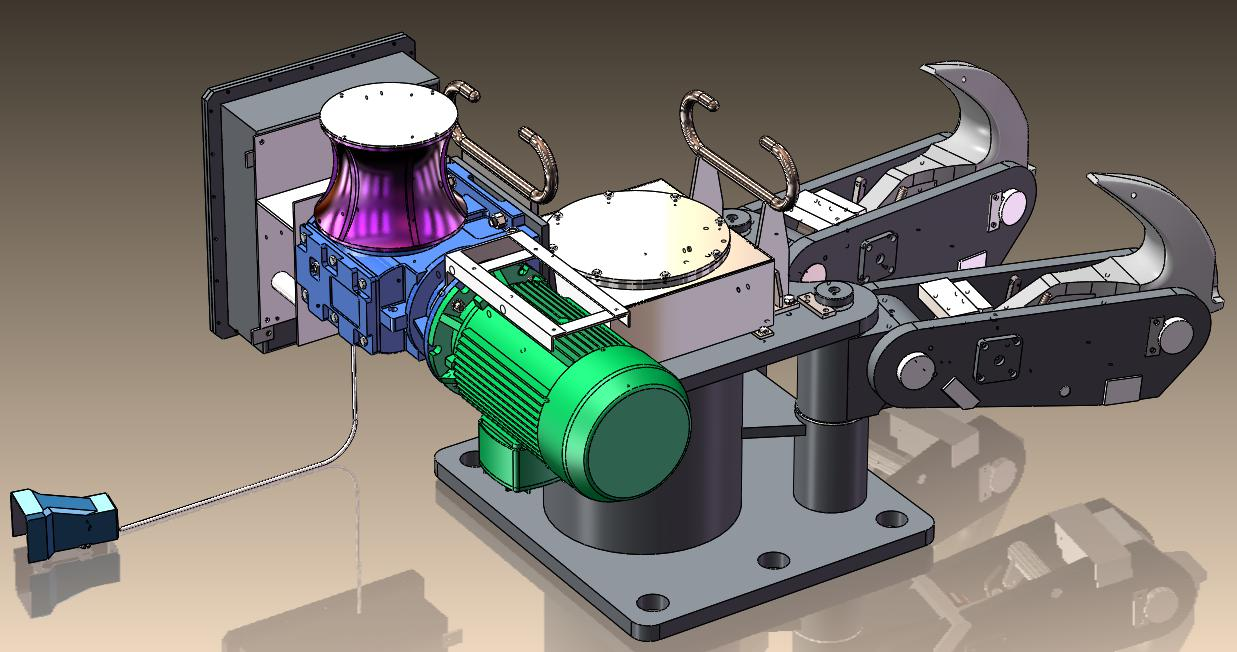

The hook is self-supporting, which allows it to be opened easily during the working movement and does not hit the dock surface under any circumstances.

Cable release hook design

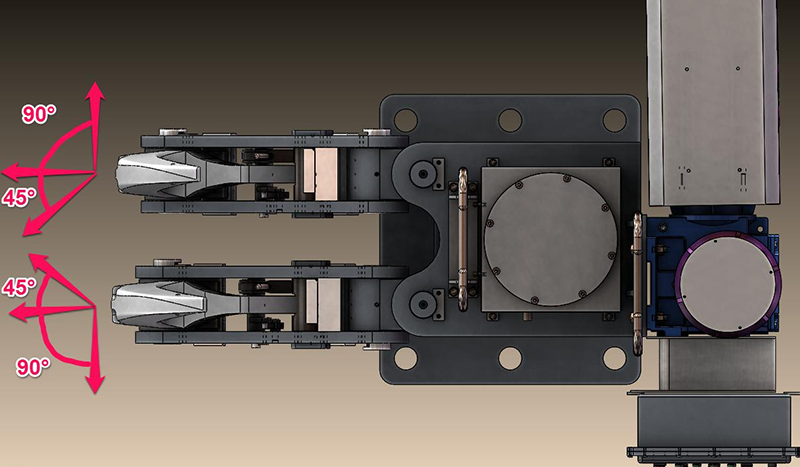

Each hook can move and rotate independently in the horizontal and vertical planes, the envelope range is shown in the figure:

Standard Specifications

The design, manufacture, installation and acceptance of quick release hooks are not limited to the following standards and specifications:

● Q/TMXW1-Quick Release Hook (Shanghai Enterprise Standard)

● GB3811-Crane Design Specifications

● GB50017-Steel Structure Design SpecificationsAnchor Hook Stress Analysis

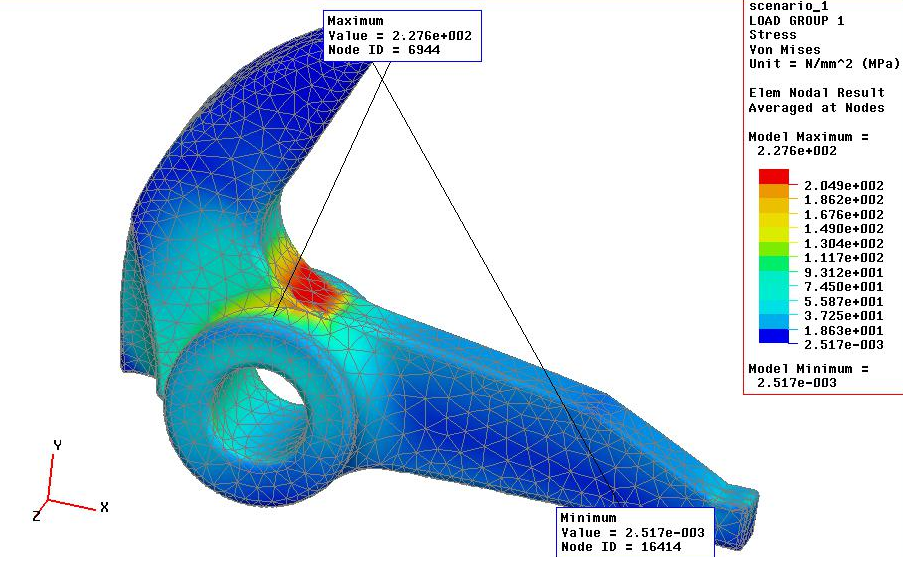

The engineers and technicians of Guanzhuo Company established a finite element model (Finite Element Model) for the anchor hook, an important part of the cable release hook, according to the load, working conditions and boundary conditions, and conducted finite element force analysis. The figure on the right is the stress deformation cloud map (fingerprint map) obtained by the analysis.

Electric winch

In order to save time and safety, the electric winch is used to pull the heavy cable of the moored ship to the release hook. The foot switch controls the rotation of the electric winch.

control Panel

Foot switch

Imported from Germany

Rust-proof aluminum alloy housing Oxidized and painted with anti-corrosion paint

Protection grade IP66 Explosion-proof grade dlICT4 AC 36V safety voltage

Standard Features

● The working part of the cable release hook, the anchor hook, is made of ASTM A27/A27 M-95 grade 20-36 cast steel or JB/T6402 high-strength alloy structural steel ZG35C rlMo, and the welded structural parts are made of low-alloy high-strength structural steel GB1591 Q345 (16Mn).

● The cable release hook is equipped with an anchor hook locking safety device and a flexible cable release mechanism, so the reaction force during cable release will not be transmitted to the manual operating lever. The operator feels comfortable and safe.

● The anchor hook can be detached independently, and the hook is designed to be suspended above the dock floor. Under any load conditions, the hook does not touch or hit the dock floor.

● The hook can be safely released under no load or at full working load. The hook assembly can absorb high impact forces and is equipped with a steel reinforced synthetic rubber buffer to absorb the impact energy generated by the hook when releasing/resetting the hook under high load conditions and the impact energy generated by the mechanism. Avoid sparks and reduce damage to the device caused by impact vibration

● Release lever can be used to release the rope easily. The hook release mechanism is set inside the structure of the hook body to prevent other nearby hooks from damaging it and making the rope unable to hang securely.

● The pin is made of 40Cr high-quality alloy steel, and the surface is hard chrome plated after grinding. All shaft pivots are equipped with grease nipples. The surface of the pin is provided with spiral oil grooves, which makes it easy to add grease and lubricate thoroughly.

● The main wearing parts of the quick release hook are all detachable, which is simple to maintain and easy to repair.● The winch and quick-release hook device are installed integrally, and there are anti-slip strips on the surface of the winch.

● The winch is designed to be maintenance-free and is tested and lubricated at the factory before delivery to ensure long-term use.

● Hydraulic remote release control

● Electric remote release control

● Load monitoring

Quality Control Tensile Testing

● The manufacturing process of the cable release hook is controlled according to the ISO9001 quality assurance system.

● The anchor hook and shaft are subjected to a tensile test of 1.25 times the safe working load (SWL).

Surface treatment and painting

● Sandblasting and rust removal treatment on steel structure surface, SA2% grade

● Thermal spray zinc

● Heavy anti-corrosion coating: epoxy zinc-rich primer, epoxy micaceous iron intermediate paint, polyurethane topcoat, total film thickness >300nm

Some recent performance of cable hook

● Sinopec-Zhenhai Refining Suanshan Wharf-Guangzhou Petroleum Xiaohu Island Wharf-Guangzhou Petrochemical Huade Company Wharf

● PetroChina-Dalian Petrochemical Oil Products Terminal

● Sinopec-Hainan Shihua Oil Products Terminal

● Shell Oil-Mabianzhou Wharf, Daya Bay, Huizhou, Guangdong

● China Gas-Shanghai Haibin Oil Terminal

● CNOOC-Ningbo Daxie Petrochemical Oil Terminal

● South Korea LG-Lixin Company-Qingdao Chemical Terminal

● Shenzhen Guanghui Petrochemical Co., Ltd.-Chemical Terminal-Spanish DPI Company-Hong Kong Huada Company

Dalian Beiliang Petrochemical Terminal Operation Site

Caofeidian Ore Terminal Operation Site

Qingdao LG Petrochemical Terminal Cable Hook

On-site use at Zhejiang Zhapu Port

CNOOC Shell (Daya Bay Mabianzhou) use site

Zhenhai Refining and Chemical Suanshan Wharf in use

Dalian Petrochemical Terminal Cable Hook

Inspection of cable hooks for export to Hong Kong

Factory inspection of cable hooks exported to the United States

Factory inspection of cable hooks exported to Brazil

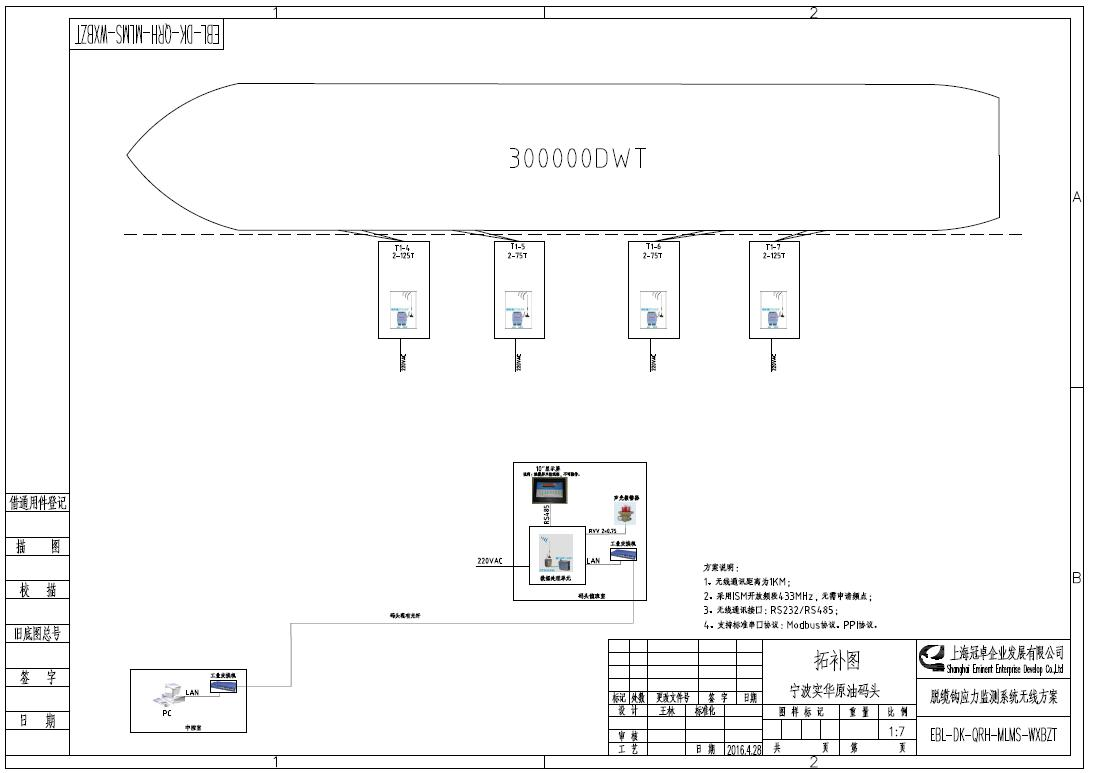

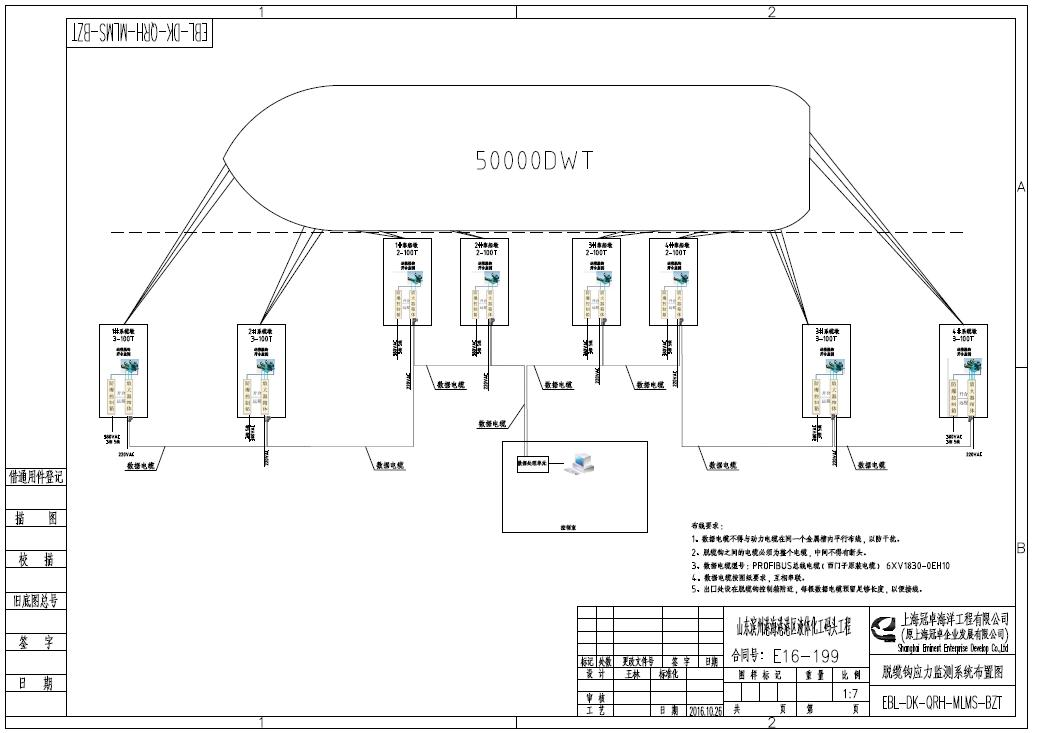

Cable release hook arrangement

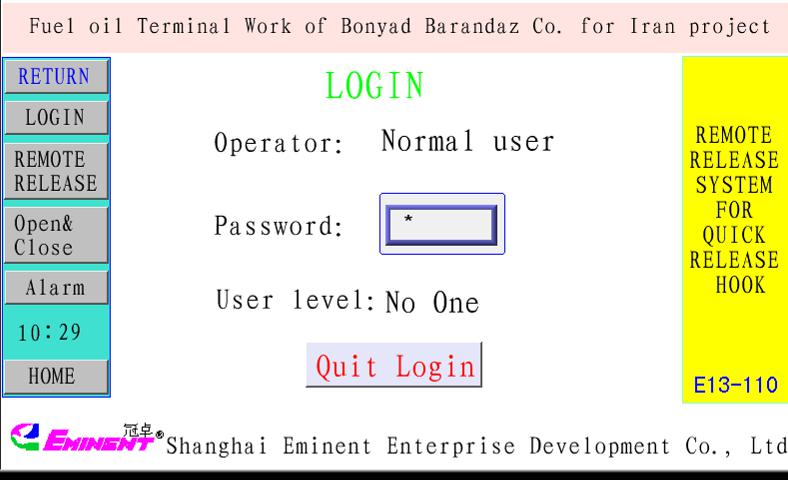

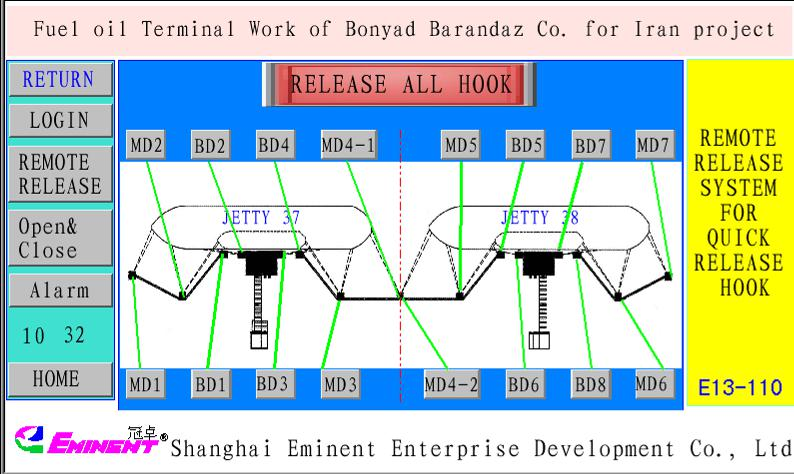

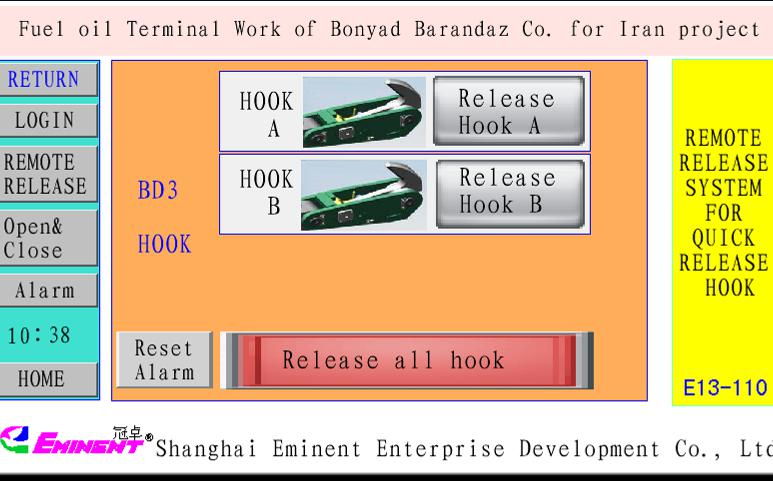

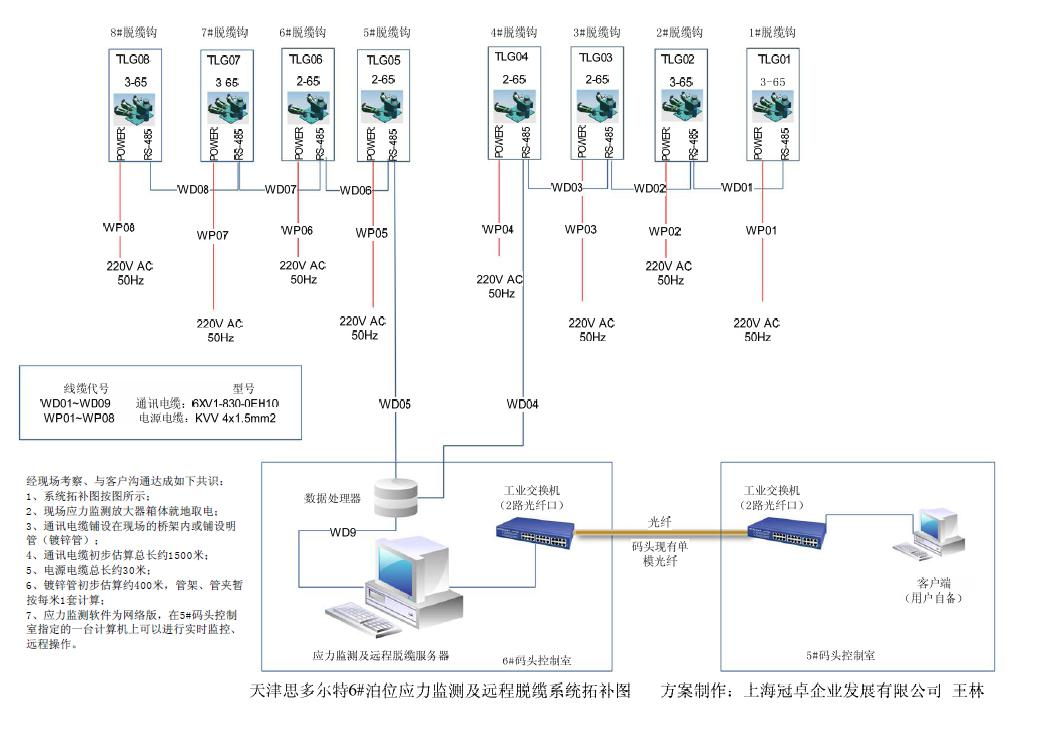

Remote release system for cable release hook

System Features

● Different levels of functions can be used by different users with different login permissions

● Can control the cable release of any hook of a single cable release hook individually, or make all hooks of a single cable release hook release, or all cable release hooks in the system release all cables

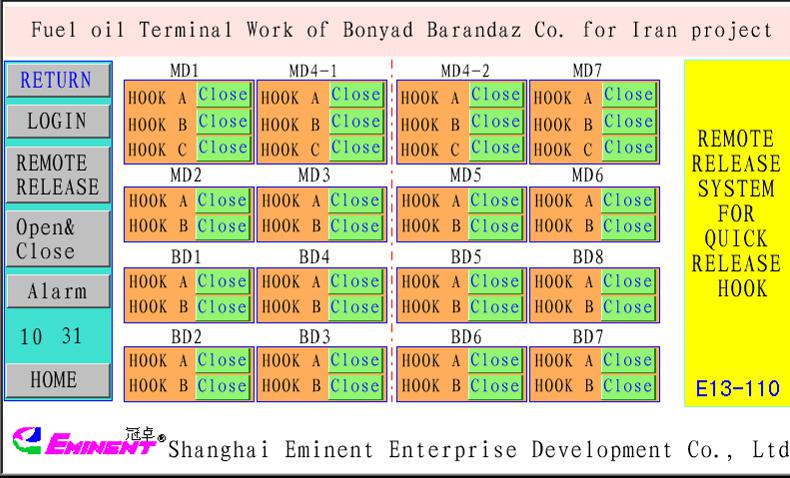

● Real-time monitoring of the status of all cable hooks in the system

● Remote sound and light alarm for abnormal cable disconnection, as well as alarm query and cancellation functions

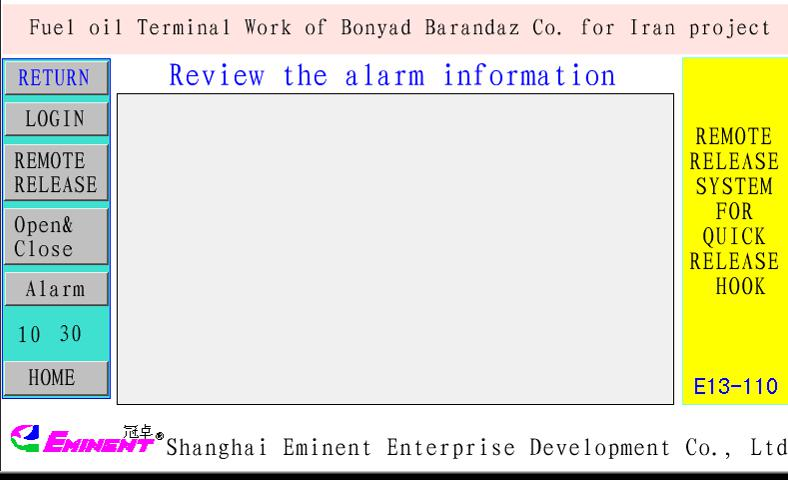

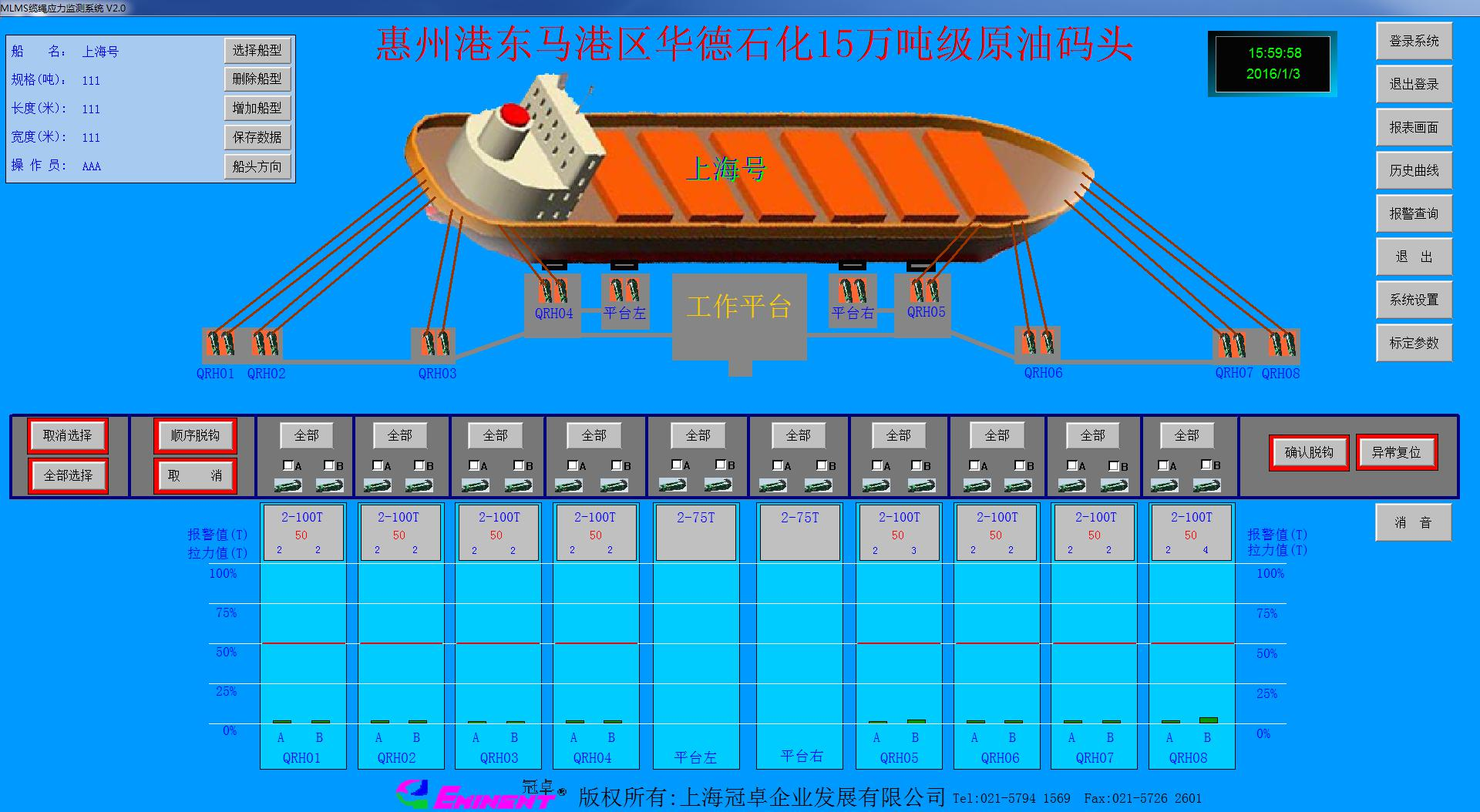

RRS function description and operation interface 1

● System login (different levels of authority can be granted according to different operators)

● Event View

● Opening and closing monitoring status

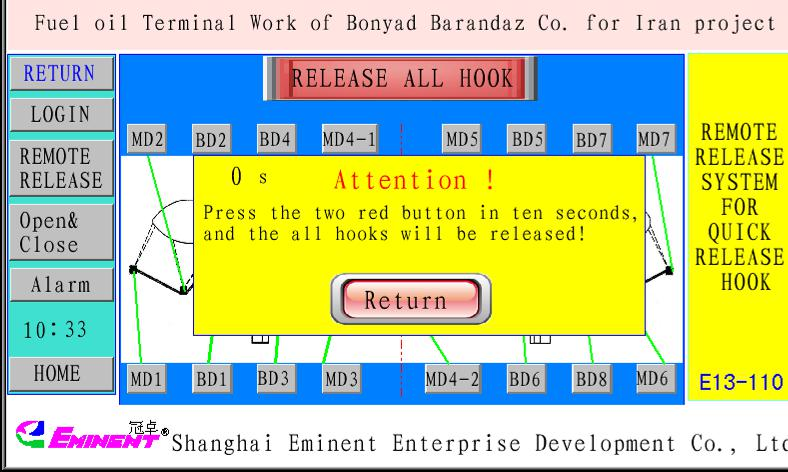

● Remote unhooking (On the remote unhooking screen, you can select any unhooking hook to perform remote operation, or perform all unhooking operations.)

● When all cable release is selected, a warning box will pop up. Press and hold the two red buttons on the control box panel at the same time within ten seconds. All cable release hooks in the system will be released.

● When a single cable release hook is selected for remote cable release, the corresponding operation screen will pop up (hook No. 1 is used as an example below). On this screen, you can perform cable release operations on hook A or hook B separately, or perform all cable release operations on a single hook.

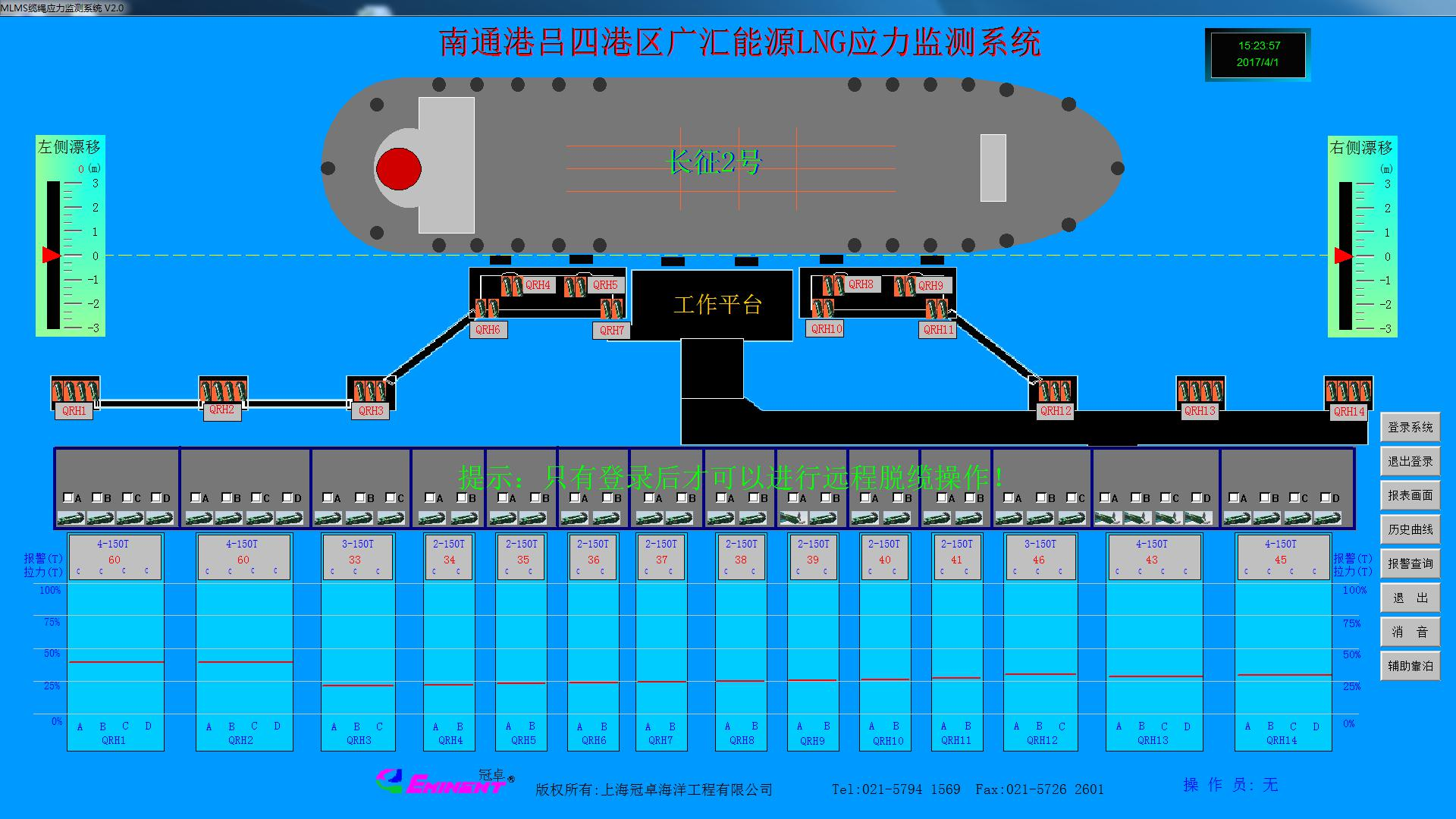

MLMS Cable Strain Monitoring System

Overview

The cable stress monitoring system monitors the cable tension of ships operating at the dock in real time, making it easier for dock operators to make timely judgments on changes in cable tension. When the cable tension exceeds the limit, an audible and visual alarm signal will be issued to remind relevant personnel to take corresponding measures to prevent cable breakage accidents.

Key Features

● It can monitor the real-time stress status of all mooring cables in the system, and display the current tension of the cables on the monitoring computer in the central control room and the local display screen;

● When the cable force exceeds the set value, the central control room monitoring computer and the local alarm signal will be issued to remind the operator to pay attention;

● Users with different login permissions can use different levels of functions;

● All data and alarm information are stored on the computer hard disk and can be played back;

● Alarm query function;

● Report printing function.

System Parameters

Working environment: -10℃~+40℃

Rated voltage: 220V, AC, 50Hz

Rated current: <5A

Communication mode: RS485

● System hardware composition

● Stress monitoring sensor

● Slave (local) data processor

● Main station (central) Data processing unit Data processing unit

● Monitoring computer

● Stress monitoring software

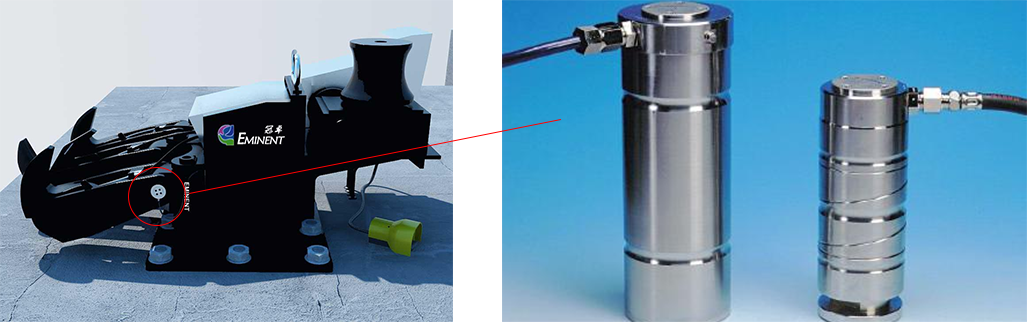

Stress Monitoring Sensors

Main parameters

Explosion-proof grade: EExd-IIBT6

Protection level: IP68

Material: 17-4PH SS stainless steel

Accuracy: 1% of full load

Measuring range: 60/100/125/150/250 T

Safety factor: 5:1

Rated output: 0.8-2mv/v

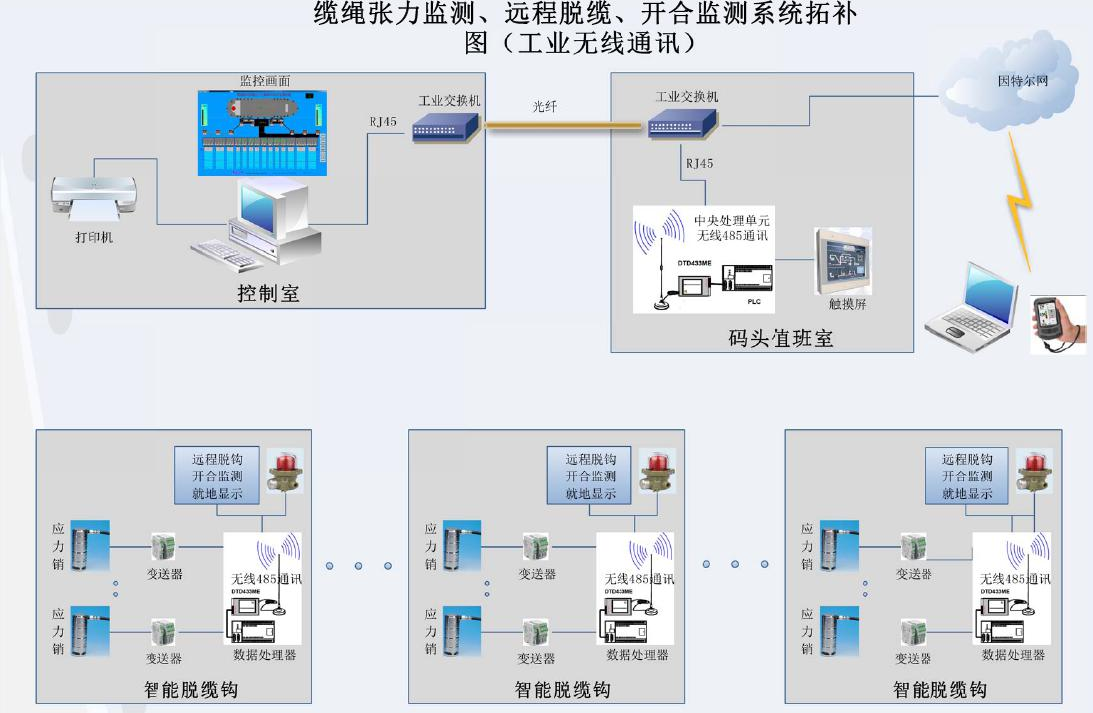

MLMS Cable Strain Monitoring System

Communication methods of each system

Master station--slave station: DP bus/bus/wireless 485 transceiver module

Monitoring host--master station: bus/LAN/optical fiber

Wireless transmission + optical fiber transmission type

Wired transmission type

Wired + optical fiber transmission dual master station

Typical monitoring screen of MLMS stress monitoring system

Portable stress pin calibration instrument

How it works

After the hydraulic jack is manually pressurized, the jack will transfer the force to the anchor hook through the load-bearing support column, and the stress state of the anchor hook is transmitted to the stress pin. The stress state of the stress pin can be monitored in real time on the stress monitoring system; the force applied by the jack can be calculated through the cylinder area and pressure value, so by comparing the two analysis force values, the stress pin calibration work can be carried out on site.

Main components: load-bearing support column, load-bearing block, and 150T manual hydraulic jack.

The components of the jack are divided into: hydraulic cylinder, manual pump, pressure gauge, gauge seat, high-pressure hose, and quick connector.

On-site calibration at Tianjin Sinochem Terminal

Dalian LNG Terminal On-site Calibration Case

Features of Guanzhuo cable hook

1. The vertical electric winch is mainly composed of an internal brake explosion-proof motor + helical gear.

2. The vertical structure and the winch height are too high, which is not conducive to operation.

3. Vertical structure, internal brake motor maintenance is inconvenient, and reliability is not as good as horizontal structure

Installation structure

1. The horizontal electric winch is mainly composed of an ordinary explosion-proof motor + a patented inclined vortex combination reducer.

2. The horizontal structure height is about 1.1 meters, which is in line with the operating height of Asians

3. The horizontal structure is maintenance-free and adopts mechanical self-locking form, which is safe and reliable

Features of Guanzhuo cable hook

The locking mechanism of the cable hook of the same manufacturer adopts a rigid hard connection. When the hook is manually released, the vibration of the hook will be directly transmitted to the hand, causing arm pain or injury

Hook locking mechanism

Guanzhuo's cable-release hook adopts a flexible locking mechanism. Even if it is fully loaded and unhooked, the vibration will not be transmitted to the arm, and its locking is safer and more reliable.

Features of Guanzhuo cable hook - stress blind area elimination

In the early stage, when we were debugging the cable release hook, we found that there was a stress monitoring blind area in the cable release hook (for the cable release hook with stress monitoring system)

In order to eliminate the stress blind area, Guanzhuo redesigned the steel structure and stress pin of the cable release hook. After countless tests, the stress blind area has now been completely eliminated.

Features of Guanzhuo Cable Hook - Material Features

The hook, connector and hook bolt of the cable release hook are all made of ZG35CrMo alloy steel, which meets the JB/T6402-2008 standard and has been heat treated. Its tensile strength σb≥985MPa, and yield strength σs≥835MPa. The hook made of this material is also very rust-resistant and corrosion-resistant. Even if the connection between the hook and the cable is worn, it can be guaranteed not to rust.

Previous Page

Next Page