- Product Description

-

Marine loading and unloading arm system: The metal steel pipe loading and unloading arm system with joints (see figure) is installed on the dock to complete the loading and unloading tasks of petrochemical products (liquids/gases). It has the ability to adapt to different tides, freeboards and hull movements. It is an efficient and safe oil terminal loading and unloading equipment.

The oil transfer arm system consists of three parts: loading and unloading arm, electrical control equipment, and hydraulic control equipment. See the figure below for the system composition.

Due to special applications, the purchase of semi-automatic arms requires accurate and complete specifications and high engineering evaluation. Therefore, loading and unloading arms cannot be expected as only standard equipment.

The uniqueness of each half arm application is reflected by the variability of the operating envelope, complexity, the media being transported, the requirements for simultaneous operations, the spacing of the gathering pipes, the dock and pipeline layout, the loading arm form, environmental loads, auxiliary equipment, etc. All of these factors are considered in the initial stages of design and accurately reflected in the final specification parameter table of the loading arm.

■ Emergency Release Device (ERC)

● The emergency release device designed and manufactured by Guanzhuo Company (patent number: ZL200420025919.8) has the following four characteristics:

● Eliminates the huge bell effect during emergency shutdown.

● The sequential shutdown method is adopted to effectively prevent the medium from entering the sea surface during emergency shutdown, reducing the pollution to the environment caused by medium leakage.

● It uses both soft and hard seals to effectively block the spread of fire and has fireproof function.

● A power pulley is set to ensure that the double ball valves can achieve 100% separation in a short time.

■ Three-dimensional joint teaching and following function

The traditional oil transfer arms, especially the large-diameter ones, have very tight three-dimensional joints, which makes it very difficult to dock with ships. The teaching device developed and designed by Guanzhuo Company allows one person to easily and freely operate the three-dimensional joint for quick docking with ships.

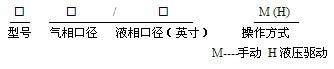

Oil loading arm specifications

◆Diameter: 4″, 6″, 8″, 10″, 12″, 14″, 16″, 20″, 24″

◆Design pressure: 0.6MPa~5.0MPa

◆Design temperature: -196~300℃

◆ Applicable media: oil products, chemicals, liquefied gas, liquid asphalt, ballast water.

For the transmission of high-temperature media, we can provide oil transfer arms with electric heating, steam heating, and insulation layers.

For the transmission of highly corrosive media, we can provide oil transfer arms with pipelines lined with PTFE and PVC.

Main technical features of oil transfer

armsRC/E type:

The oil transfer arm is designed as an independent support structure. It adopts a large-diameter slewing bearing coaxial with the rotary joint to bear the structural load, wind load and tipping distance. It adopts rope pulley rotation balance and is suitable for 6″, 8″, 10″, 12″, 14″, 16″, 24″ large-diameter oil transfer arms and double-tube arms. 5,000~300,000 ton ships.FB/E type:

simple structure, self-supporting structure, all loads are borne by the rotating joint. Double counterweight balance is adopted, suitable for 3″, 4″, 6″, 8″ and small-diameter oil transfer armsEA type:

self-supporting structure, rope pulley rotation balance, suitable for 4″, 6″, 8″, 10″, 12″ medium-caliber oil transfer arms. 500~30,000 ton ships.■ Oil transfer arm selection guide

Oil transfer arm quantity and specification determination

When determining the model, quantity and diameter of the oil transfer arm, the following factors should be considered: product type and characteristics Loading and unloading efficiency, flow rate (the oil transfer arm allows a flow rate of ≤11m/s), pressure loss Ship oil transfer arm selection guide, terminal piping model and terminal space Loading and unloading space The selection of loading and unloading capacity should be considered

Optional configuration of oil loading arm:1. Vacuum short circuit device

2. Drain connector

3. Purge system

4. Emergency ladder

5. Adjustable legs

6.Hand/liquid quick connector

7. Insulation flange

8. Over-limit sound and light alarm system

9.Electro-hydraulic drive system

10. Emergency disconnect connector (ERC)

11. Electric heating

12. Steam tracing

Oil delivery arm diameter and number selection table

Layout of oil loading arm:

Since the tanker manifold flange is usually located in the middle of the ship, the oil transfer arm should be arranged at the front of the middle of the berth. The distance A1 from the center of the oil transfer arm column to the front of the dock can be selected according to the following table.

When installing multiple oil transfer arms, the center distance between adjacent columns should be determined according to the size of the oil transfer arms, the range of movement and the spacing between the oil tanker pipes, and selected according to the table.

Previous Page

Next Page