Land-based fluid loading and unloading arm (crane pipe)

Retail Price

Market price

Weight

Inventory

隐藏域元素占位

Land-based fluid loading and unloading arm (crane pipe)

Classification:

Reservoir Products

- Product Description

-

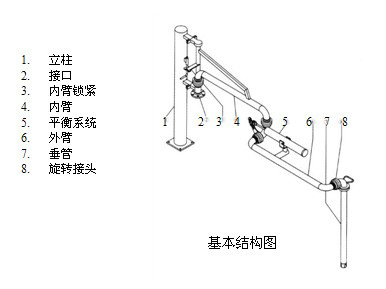

The crane pipe product is a mobile device that uses a rotating joint to connect with rigid pipes and elbows to achieve the transmission of liquid media between fire, automobile tank trucks and trestle storage and transportation pipelines, replacing the old hose connection. It has the characteristics of high safety, flexibility and long life.

● The key parts of the crane pipes produced by Guanzhuo Company are made of alloy steel and stainless steel, processed by precision CNC machine tools, and have a built-in double-roller support structure, which is flexible in rotation, light and reliable.

● The sealing structure is unique, using PTFE reinforced polytetrafluoro material, which has excellent wear resistance. The sealing surface is polished, with superior sealing performance, reliability, good sealing and long service life.

● Used for loading and unloading highly corrosive media. Based on the original pipeline, special structural sealing rings and PTFE-lined steel pipes are used to load and unload highly corrosive chemical media such as acids and alkalis.

● Carbon steel pipes for conveying media adopt GB8163 standards, and stainless steel pipes adopt GB/T14976 standards.

● Reasonable spring cylinder balance system can achieve balance in any situation. The crane pipe alignment operation is light and convenient. One person can operate it easily.

● All pressure pipeline welds are made of argon arc welding and undergo strict flaw detection and pressure testing, meeting HG/T21608 standards.

● The crane pipes used for loading and unloading flammable and explosive media are equipped with high-quality and well-designed electrostatic grounding systems with an electrostatic resistance of less than 2Ω and reliable safety performance.

● Reasonable structure, with the smallest possible arm size to achieve the largest possible envelope range.

●The surface shot blasting is used to remove rust, high-quality paint, and reasonable spraying technology to ensure the high quality of the surface paint and can well meet the anti-corrosion requirements.

● The crane pipe is strictly inspected and tested according to HG/T21608, and its performance parameters can be guaranteed.

● Guanzhuo Company carries out whole-process quality control on product design, manufacturing and service according to ISO9001 quality system standards.

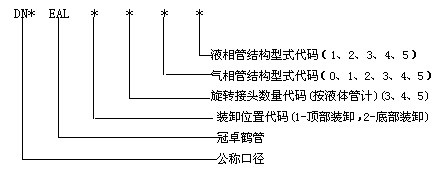

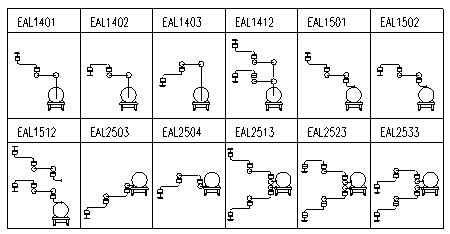

■Crane pipe specifications and models

Nominal diameter: DN25, DN50, DN80, DN100, DN125, DN150, DN200

Working temperature: -196~300℃

Working pressure: -0.08~5.0MPa

Applicable media: oil, chemicals, liquefied gas, liquid asphalt, water.

■Crane pipe selection guide

The selection of crane pipe type is determined by the vehicle type, loading and unloading method, installation method of the crane pipe on the trestle, medium, loading and unloading process and other conditions. For example:

● For open top unloading of tank cars, EAL1403 can be selected and equipped with gas/hydraulic submersible pumps.

● For closed loading and unloading of liquefied gas on the top of the train tank car, EAL1512 can be selected and connected to the tank car with a flange interface.

● For the closed bottom unloading of crude oil in train tank cars, EAL2503 can be selected. A heat mixing device can be configured.

● For closed loading on the top of tank trucks, EAL1412 can be selected, and the return air pipe can be configured as a metal hose. Liquid level alarm can be configured.

● For the closed loading and unloading of liquefied gas at the bottom of the tank truck, EAL2533 can be selected and connected to the tank truck with a quick connector.

■Optional accessories